Project significance:

Additive manufacturing (3D printing) has a huge advantage in customizing implants, with the medical market for personalized implants expected to reach $9.639 billion by 2024. PEEK (polyetheretherone) material is considered as the next generation of bone implant material, which overcomes the disadvantages of metal material such as stress shielding and radiation artifact. At present, the advantages of PEEK materials are combined with 3D printing technology, which can change the shortage of implant materials in the past and realize the rapid manufacturing of customized PEEK bone implants. However, in order to meet the requirements of further clinical applications, such as the biomimetic function of bone implants, the strong bone-peek-soft tissue biological binding requirements, and the controllable mechanical properties, this project proposes the additive manufacturing technology and medical application of customized functional biomimetic PEEK bone implant, aiming to break through the existing homogenized PEEK implant manufacturing method, develop biomimetic functions of customized implant material, design, manufacturing and evaluation technology, and provide innovative technology and industrialization support for the future industrial development.

Research content:

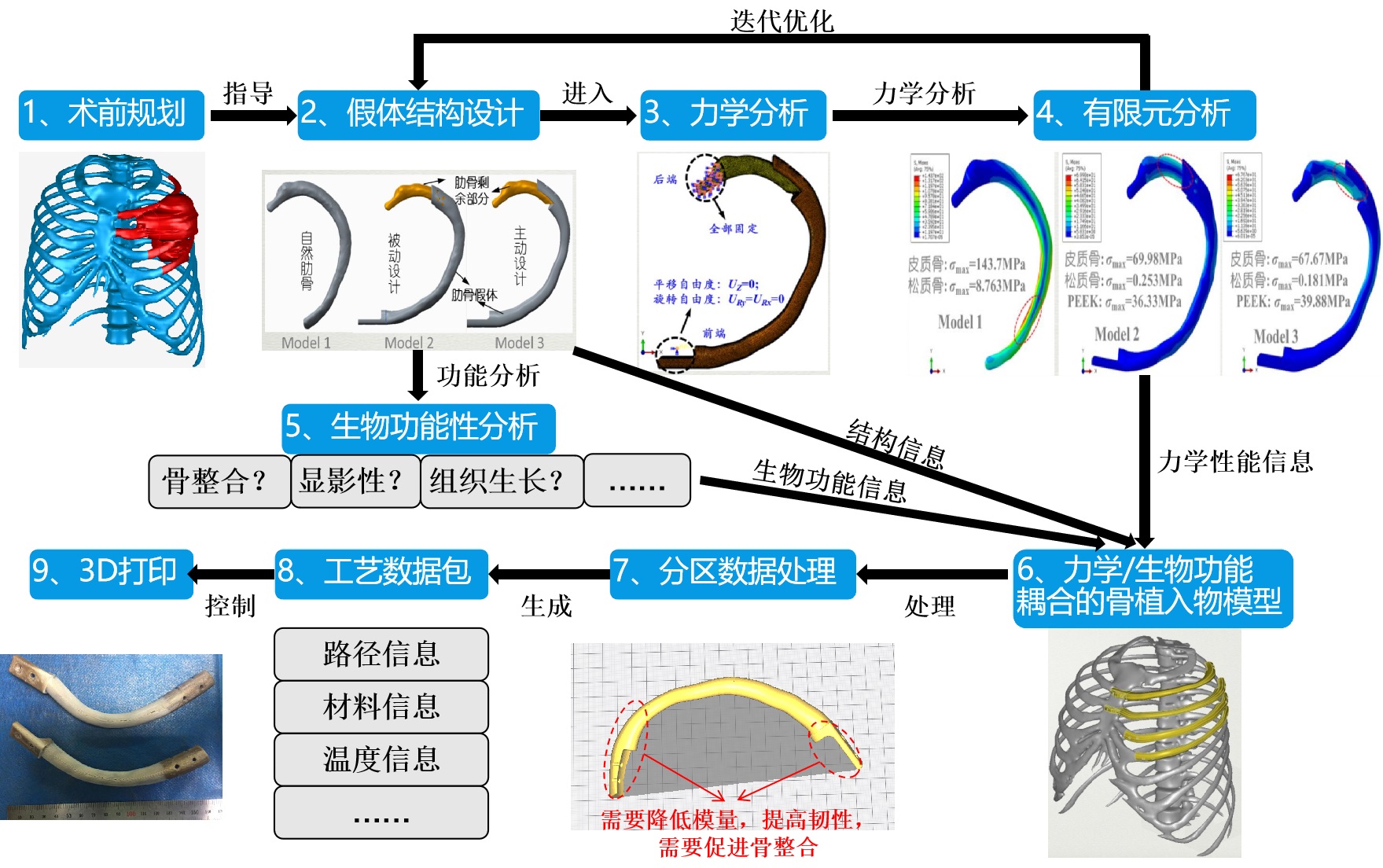

? Research on the design method of functional bionic PEEK Bone implant

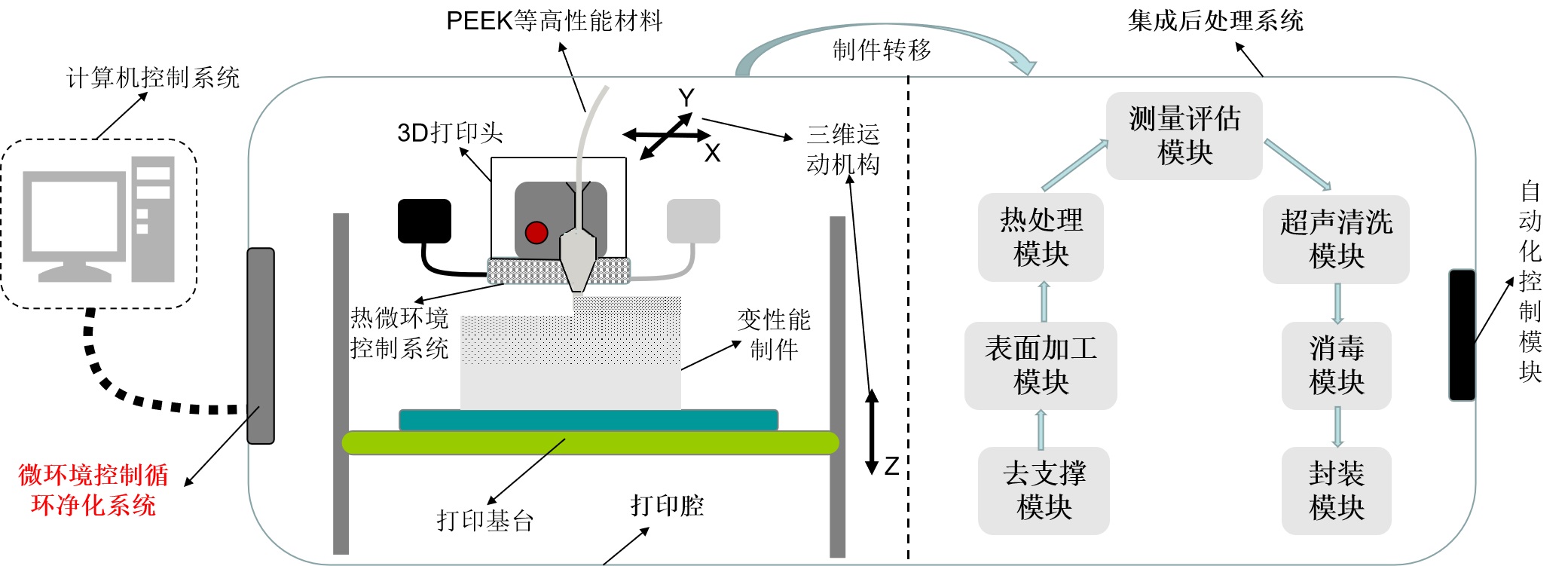

? Developing of 3D printing equipment for multi-material melting deposition process

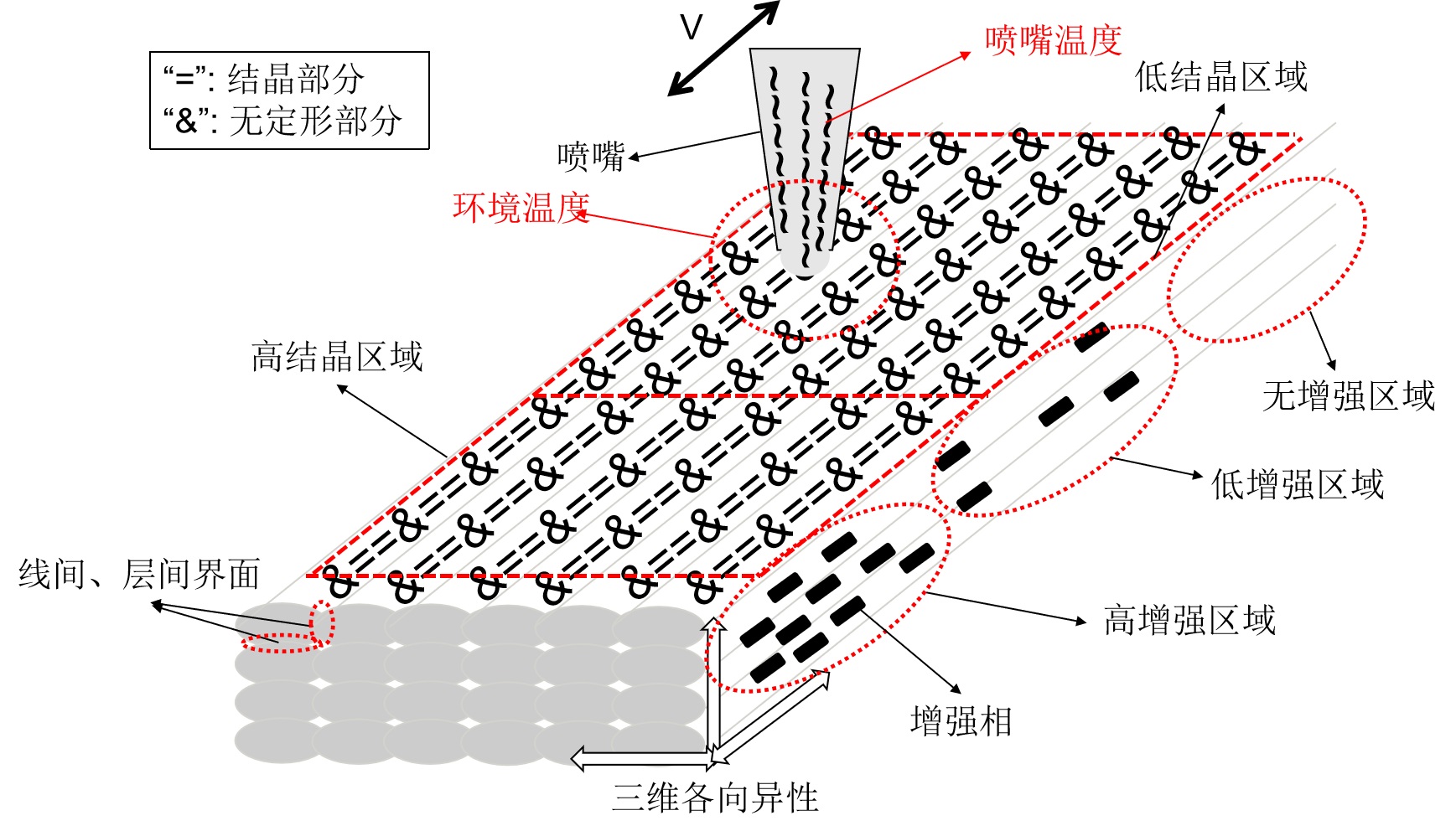

? Study on local crystallization regulation and multi-material controlling technology

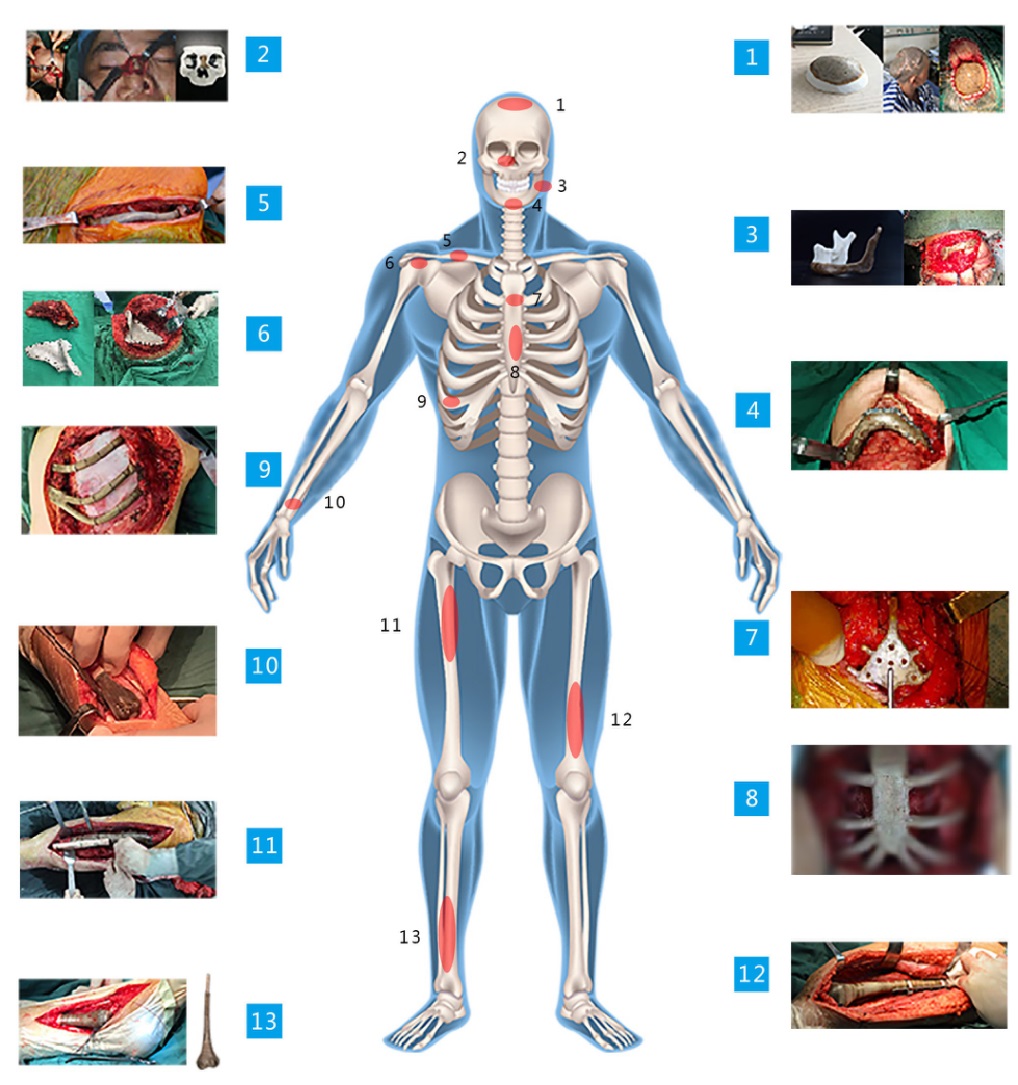

? Clinical applications of customized PEEK functionalized implants

Figure 1. Design technology of functional biomimetic PEEK bone implant

Figure 2. Plan of 3D printing equipment for multi-material melting deposition process

Figure 3. Mechanism of local crystallization regulation and multi-material controlling technology

Application prospect:

Now with more than 30 hospitals, we have realized hundreds of clinical cases of 3d printed customized PEEK bone implants, range of neurosurgery, maxillofacial surgery, dental, thoracic surgery and orthopaedics department, which account for more than 98% of international reported cases, including many the first clinical application. This project has been continuously promoting the development of customized medical device industry. In the near future, it will promote the formation of a group of medical devices of 3D printed customized PEEK bone implant, which are admitted by national regulatory authorities, promoting the development of precision medicine industry.

Figure 4. Clinical applications of customized PEEK functionalized implants